salt spray chamber astm b117|astm b117 salt spray specification : tv shopping Salt spray chambers and the ASTM B117 standard are vital tools in the fight against corrosion. They help manufacturers ensure that their products can withstand harsh . {{page.description}}

{plog:ftitle_list}

Champions League, Brasileirão, Libertadores, Copa do Brasil e muito mais! Futebol Ao Vivo Online Grátis Sem Travar Tv Online Ao Vivo Grátis e em HD

Our customers request ASTM B117 Salt spray and fog testing for a variety of reasons, Including: 1. To assess and compare the corrosive resistance of different metals or finishes. 2. To determine the corrosive tendencies in case of scratches on metal or coated surfaces (Combine with ASTM D1654 for . See moreThe outcomes of a B117 Salt spray Test include the ability to assess the corrosion resistance or suitability of coatings, paints, and metals for exposure to corrosive environments . See moreOur experts recommend avoiding ASTM B117 as the corrosion test standard if your product incorporates decorative chromium plate (nickel-chromium) on steel, zinc die castings, or cadmium . See more

custom mooncity 3-in-1 soil tester moisture meter

Following an ASTM B117 test, our corrosion experts will issue a test report, which will typically show: 1. Photographs of the test samples pre & post exposure, or at any specified . See more Salt spray chambers and the ASTM B117 standard are vital tools in the fight against corrosion. They help manufacturers ensure that their products can withstand harsh .

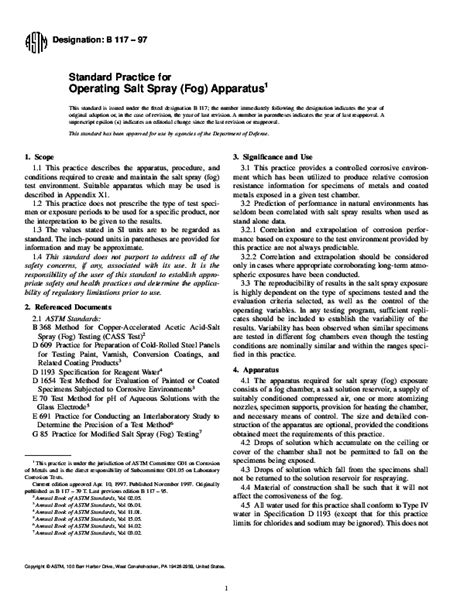

In ASTM B117 testing, specimens are exposed to corrosion using a chamber that accelerates time and salt exposure. The chamber's temperature and the solution's pH levels typically remain the same throughout the test. The test's length depends on factors like the given material, product and intended use. . ASTM B117 Salt Spray Test: Procedure . Standard Practice for Operating Salt Spray (Fog) Apparatus B0117-19 ASTM|B0117-19|en-US Standard Practice for Operating Salt Spray (Fog) Apparatus Standard B117 Standard Practice for Operating Salt Spray (Fog) Apparatus> new BOS Vol. 03.02 Committee G01 $ 76.00 In stockASTM B117 is a document establishing the parameters and requirements for operating a salt spray test chamber. It specifies how to create and maintain the salt fog test environment so that results can be achieved consistently from lab .

The ASTM B117 standard, also known as the “Standard Practice for Operating Salt Spray Fog Apparatus,” is an essential guideline in the field of corrosion testing. This practice defines the standard conditions for operating salt spray fog apparatus to assess the corrosion resistance of various materials. Q&As on Operation of Salt Fog Test Chambers: The Salt Spray Woes, pH, S.G., Volume of Condensate too low, Concentration too low, etc. . ASTM B117 Salt Fog Test Chamber Operational Q&As, Problems: Salt Spray Woes. Q. With what solution can I unclog the nozzle if it has grains of salt stuck?

This process helps predict the lifespan of coatings and materials when exposed to salt spray or sea water. Types of Salt Spray Chambers. Traditional Salt Spray Chambers: These are the most common and are used primarily for continuous salt spray tests as per ASTM B117. They help evaluate the corrosion resistance of electroplated layers and anti . ASTM B117-19 covers the apparatus, procedure, and guidelines to create and sustain the salt spray (fog) test environment. It is important to note that the standard does not prescribe the interpretation of the results.Designation: B117 − 19 Standard Practice for Operating Salt Spray (Fog) Apparatus1 This standard is issued under the fixed designation B117; the number immediately following the designation indicates the year of . 7.1 The position of the specimens in the salt spray chamber during the test shall be such that the following conditions are met: The salt fog test ASTM B117, also known as the salt spray fog testing, is a widely recognized standard for evaluating the durability of materials and coatings. . Salt Spray Test Chamber for ASTM B117. Tensile Testing Machine. Single Column Universal Material Testing Machine; Drop Test Machine; Tumble Tester;

I-This method is applicable to salt spray (fog) testing of ferrous and non-ferrous metals, and is also used to test inorganic and organic coatings, etc., especially w'here such tests are the basis for material or product specifications. 2. Apparatus 2.1 The apparatus required for salt spray (fog) testing consists of a fog chamber, a saltThe Atlas SF Series are rugged and reliable chambers for traditional Salt fog (spray) and Humidity Testing. SF cabinets are used to quickly qualify a coating or material on a pass-fail basis, or determine the probability of corrosion of a specific material. . ASTM B117, ASTM D1735, ISO9227, GM 4429P, GM 4465P, CASS, SWAAT, Acetic acid, Water .

The Auto Technology Company Standard Salt Fog Cabinet is the basic unit that has served the testing community for over 50 years. Constructed of steel and utilizing a water jacket temperature control system these units are designed to provide the user a robust, simple design to handle the traditional test specifications like ASTM B117 (Salt Fog), Mil-Std-883, Method 1009.5, G85 A1 .

SS and SSe Series Salt Neutral Spray Corrosion Chambers (Salt Fog), also known as the Salt Mist Chamber, were built to meet the requirements of ASTM B117, ISO 9227 Neutral, CASS, AASS – JIS Z 2374 Neutral, CASS, AASS and DIN 50021.. The following are construction characteristics of the equipment that are very important to ensure the repeatability and .The ASTM B117 salt fog test standard calls for the temperature to be 35⁰C and relative humidity to be 6.5pH to 7.2pH. The salt atmosphere is to be five parts sodium chloride to 95 parts water. . The primary test equipment required for salt-spray testing is a salt fog chamber. In addition to completing testing within its lab, Keystone . The Role of ASTM B117 The ASTM B117 standard is the most widely used protocol for conducting salt spray tests. Established by ASTM International, this standard provides clear guidelines for setting up and operating a salt spray chamber, ensuring that results are consistent and reliable across different tests and industries. Key Features of ASTM .

inside the chamber, and never underneath samples or anything else that could drip into them from above. • Photographs may be taken of the samples at customer specified intervals throughout the test. CorroSalt for Salt Spray Testing (Accessory No: SALA530) Highest purity salt for fully compliant testing. For all salt spray testing including .Applied Technical Services offers ASTM B117 testing services that determine the corrosion resistance qualities of metals and coated metals. Our accredited salt spray testing lab conducts accelerated corrosion testing that simulates real .The most common type of salt spray testing is Neutral fog in accordance with ASTM B117 & ISO 9227. Where specimens are exposed to a steady stream of neutral fog, atomised inside a sealed inert chamber.

Our durable salt spray testing chambers can test a number of test specimens of many sizes, shapes and dimensions for the ASTM B117 Salt Spray Test. We can also control the duration/timing of the exposure for the test according to specific to customers requirements.1 | ASTM B117 How to Run ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus Andy Francis – Marketing Director. Bill Tobin –Senior Technical Marketing Specialist. Dave Duecker – Senior Technical Marketing Specialist. Sean Fowler –Senior Technical Director. Q .The chamber maintains a temperature of 95°F with humidity approaching 100%. Throughout the exposure period, the salt spray is monitored for dispersion throughout the chamber as well as for concentration, temperature, and pH level of the solution. . ASTM B117 salt spray test itself does not set a required duration for exposure; other .

Let us go a little more into detail on three of the main standards our Salt Spray Chamber meets : ASTM B117: This is the most common standard which has widely been accepted in the concerns of salt spray testing. It basically offers operating conditions for a salt fog apparatus, such as conditions to be maintained by temperature, humidity, and .

ASTM B117 or salt spray test takes these products/materials and exposes them to controlled conditions to measure these corrosive properties. ASTM D610 is one of the many corrosion specifications used to evaluate samples that have been exposed. . Salt Fog Testing Chamber. ATC Test Lab is the Largest Contract Corrosion Test Lab. We have over .ASTM B117 Testing – Operating Salt Spray (Fog) Apparatus Study Date: January 2014 Salt Spray chamber used: MI-EQ-477 – Model CTT 1100 – 13-1152-40 Panels used: UNS G10080 steel plates 76 x 127 x 0.8 mm Data source: ASTM B117-11 X3.8 Precision and Bias - Steel Panel Test The ASTM repeatability study gives the acceptable limits (with a 95% .

ASTM B117 is not a test specification per se, according to ASTM International. Instead, it outlines standard practices for operating salt spray (fog) equipment. ASTM B117 is a document that establishes operating parameters and requirements for salt spray test chambers. It details how to create and maintain a salt spray test environment so that .Salt Spray Test Chamber – ASTM B117 . Indirect heating of the internal cabinet through the water jacket (ASTM B117), ensuring great homogeneity of the internal temperature of the test cabinet. US PATENT # 10371623 . 2 6555 Powerline Road – Suite 405 • Fort Lauderdale, Florida 33309 • Ph.: 754.900.7816 The standards ASTM B117, ISO 9227, and JIS Z 2371 play a crucial role in supporting manufacturers in the domain of salt spray testing. Firstly, these standards provide manufacturers with universally accepted guidelines, ensuring consistency and reliability in the evaluation of corrosion resistance for metallic materials.

astm b117 standard pdf

webI. Samynha Silva Portal do Zacarias: Mistério e Tragédia em Teresina. 1. Apresentação da tragédia que ocorreu em Teresina, Brasil, envolvendo Samynha Silva e o Portal do Zacarias. Na noite de Domingo, 30 de, ficará marcada como um dos momentos mais sombrios na história de Teresina, a capital do Piauí, Brasil.

salt spray chamber astm b117|astm b117 salt spray specification